The Ultimate Guide to Custom Patches: Styles, Materials, & Customization

Turn Your Brand Identity into a Tangible Asset

At 24HourWristbands.com, we understand that a patch is more than just a piece of fabric—it is a symbol of identity, achievement, and belonging. Whether you are outfitting a police department, creating merchandise for a motorcycle club, or designing letters for a varsity jacket, the quality of your patch reflects the quality of your organization.

While we are famous for our wristbands, our custom patch manufacturing capabilities are equally robust. We offer a comprehensive range of materials—from traditional embroidered thread to rugged PVC and premium leather—ensuring that your vision is executed perfectly.

This guide explores every aspect of custom patch creation, helping you choose the right style, backing, and border for your specific needs.

Part 1: Choosing Your Custom Patch Style

The first step in your design journey is selecting the right material. Different patch styles offer unique textures, durability levels, and aesthetic qualities.

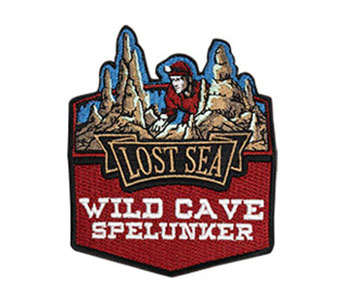

1. Custom Embroidered Patches: The Classic Standard

Embroidered patches are the most popular style in the world, recognizable by their textured feel and classic appearance. They are created by stitching high-quality rayon or polyester thread onto a durable twill fabric backing.

- Why Choose Embroidery? This style creates a 3D "lift" where the thread sits on top of the backing, giving the design depth and a high-value look. It is the industry standard for scout uniforms, employee uniforms, and security

- Coverage Options:

- 50% Embroidery: The design uses the colored twill backing as the background. This is cost-effective and keeps the patch flexible.

- 75% Embroidery: Most of the surface is covered in thread, with only small amounts of twill showing.

- 100% Embroidery: The entire surface of the patch is stitched with thread. This is the premium option, offering a luxurious, fully finished look perfect for high-end brands.

2. PVC (Polyvinyl Chloride) Patches: Rugged & Waterproof

If your gear faces harsh elements, embroidered patches might not be enough. PVC patches are made from a soft, flexible rubber-like plastic that is virtually indestructible.

- The Tactical Advantage: PVC is waterproof, mud-proof, and won't fray or fade in the sun. This makes it the #1 choice for airsoft teams, military units, and outdoor backpacks.

- 3D Sculpting: Unlike embroidery, PVC allows for true 3D layering. We create a metal mold where your design is recessed or raised. This allows for sharp, crisp details and a tactile feel that thread cannot replicate.

- Color Matching: We can match your brand colors using exact Pantone (PMS) matching, ensuring your logo looks identical to your digital art.

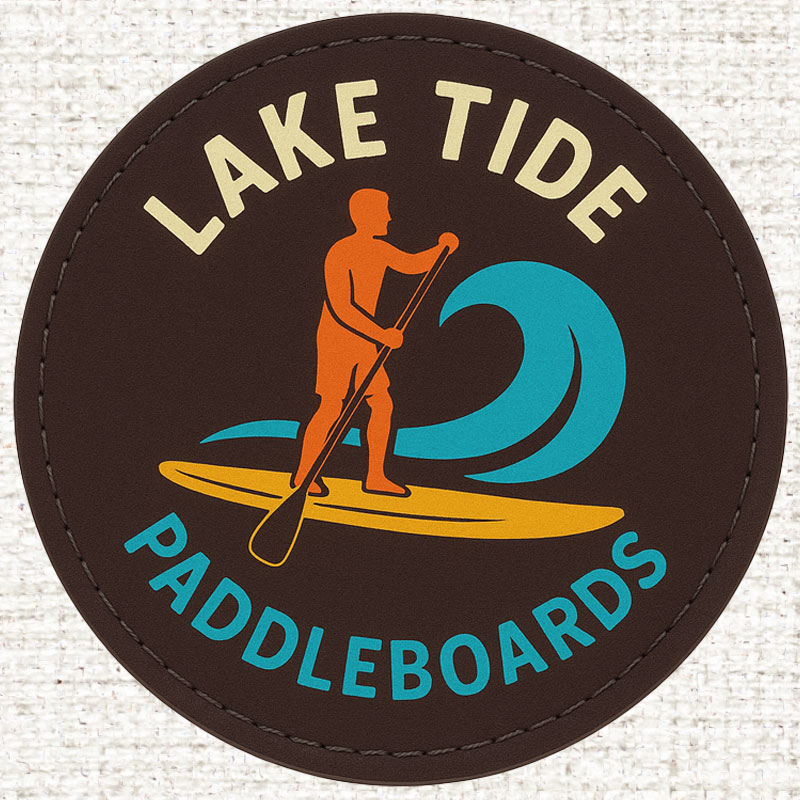

3. Custom Leather Patches: Premium & Rustic

For fashion brands, breweries, and hat makers, leather patches offer a sophisticated, organic aesthetic that implies quality.

- Material Options:

- Genuine Leather: The real deal. It ages beautifully and develops a patina over time.

- Faux Leather: A cruelty-free, cost-effective alternative that looks nearly identical to real leather.

- Decoration Methods:

- Debossed: Your logo is heat-pressed into the leather, creating a sunken, "stamped" effect.

- Laser Etched: A laser burns the top layer of the leather to reveal a darker contrast tone.

- Best Uses: Leather patches are the standard for trucker hats, beanies, and denim jeans branding.

4. Chenille Patches: The Varsity Look

If you want that vintage, "fuzzy" look seen on high school letterman jackets, Chenille is the answer.

- Texture & Construction: Chenille is created by stitching loops of wool or acrylic yarn onto a felt This creates a soft, carpet-like texture that is distinctively retro.

- Design Tips: Chenille is best for large, simple shapes (like letters or mascots). We often combine Chenille with embroidery—using embroidery for the fine text details and Chenille for the large, fluffy fill areas.

5. Woven Patches: High Detail, Flat Profile

Often confused with embroidery, woven patches are different. Instead of stitching thread onto a backing, the threads are woven together to form the fabric itself (similar to how a clothing label is made).

- When to Choose Woven: If your logo has tiny text or complex details that embroidery blurs, go woven. The thinner threads allow for much higher resolution. The patch is also thinner and flatter, making it ideal for lightweight clothing or sportswear where a heavy patch would weigh down the fabric.

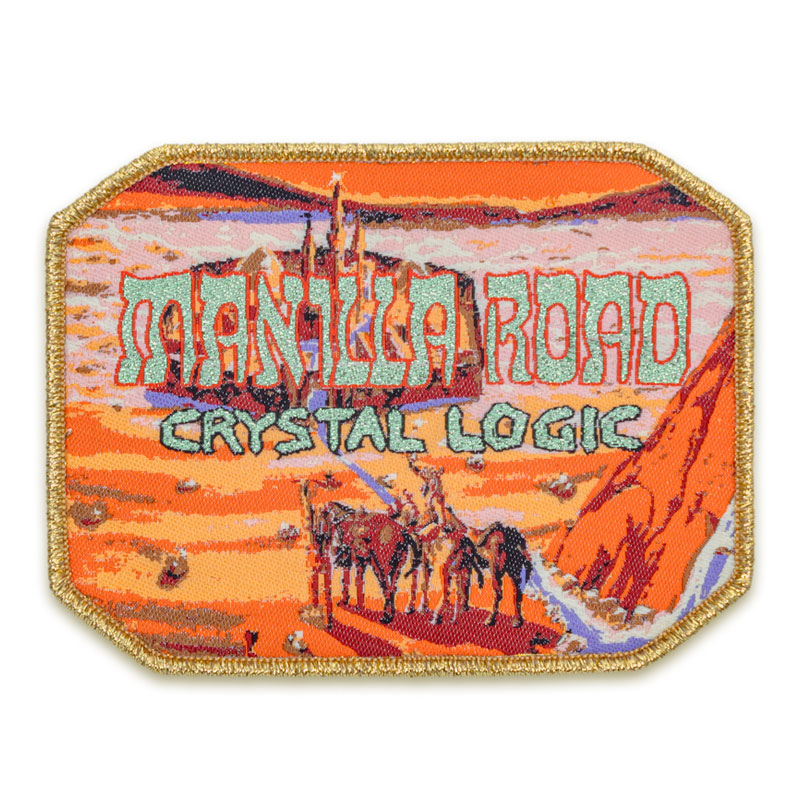

6. Sublimated (Printed) Patches

For photo-realistic designs, gradients, or infinite colors, printed patches (dye sublimation) are the solution. We dye the image directly into the fabric molecules. This allows for shadows, fades, and details that no thread-based method can achieve.

Part 2: Backing Options – How to Attach Your Patch

The "backing" is how your patch attaches to your garment. Choosing the correct backing is just as critical as the design itself, especially for functionality.

1. Velcro (Hook and Loop) Backing

The term "Velcro" is often used to describe hook and loop fasteners. This is the preferred backing for tactical gear, military uniforms, and airsoft vests.

- How it Works: We sew the "hook" side (the scratchy side) to the back of your patch. We also provide the matching "loop" side (the soft side) which you can sew onto your garment if it doesn't already have a panel.

- Benefits: It allows for instant swapping of unit patches, morale patches, or name tags without damaging the clothing.

- Durability: Our hook and loop connections are rated for thousands of peels, ensuring they won't fall off during activity.

2. Iron-On (Heat Seal) Backing

Iron-on patches are the most popular choice for consumer use because they are fast and easy to apply at home.

- The Technology: A layer of solid adhesive is applied to the back of the patch. When heated, this glue liquefies and bonds into the fibers of the fabric.

- Application Instructions:

- Set your home iron to the hottest setting (usually "Cotton"). Do not use steam.

- Place the patch on the garment.

- Cover the patch with a thin pressing cloth or parchment paper to protect the threads.

- Press down firmly for 30–45 seconds.

- Iron the inside of the garment (behind the patch) for another 20 seconds.

- Let it cool completely. The bond reaches full strength after cooling.

- Limitations: Iron-on works best on cotton and polyester. Do not use it on nylon, rayon, or rain jackets, as the heat may damage the fabric and the glue won't stick effectively.

3. Adhesive (Peel and Stick) Backing

Think of this like a heavy-duty sticker.

- Use Case: Perfect for temporary events, conventions, or single-use costumes where you want to remove the patch later without leaving residue.

- Note: This is not a permanent solution for laundry.

4. Plastic Backing (Sew-On)

If you plan to sew your patch on, we recommend a plastic backing. This is a thin layer of stiff plastic lamination applied to the back of the patch.

- Purpose: It gives the patch rigidity, preventing it from bunching up or wrinkling over time. It helps the patch maintain its shape flat against the sleeve or chest of a jacket.

Part 3: Border Options – The Finishing Touch

The border prevents the patch from fraying and frames your design.

- Merrowed Border: This is the standard "piped" edge seen on most patches. A specialized machine wraps thread around the edge of the patch, creating a thick, raised overlock stitch. It is durable and classic but works best on simple shapes (circles, squares, shields).

- Hot Cut (Laser Cut) Border: For custom shapes with sharp angles or complex outlines (like the outline of a car or a skull), a merrowed border is too thick. Instead, we laser-cut the edge, which seals the fabric and thread instantly. This creates a flat, sharp edge that traces your design perfectly.

Part 4: Usage Scenarios & Industry Applications

Our custom patches are used across every industry. Here is how different sectors utilize our products:

- Corporate & Business: Companies use embroidered patches on hats and polos to build brand consistency. A patch often looks higher value than direct embroidery and can be stocked and applied to garments as needed.

- Law Enforcement & First Responders: Police, fire, and EMS departments rely on our high-visibility, durable patches for uniforms. We often use reflective thread options for safety in low-light conditions.

- Motorcycle Clubs: Biker patches (often called "colors") require large back patches. We specialize in oversized embroidery and multi-piece "rocker" sets for leather vests.

- Fashion & Retail: Clothing lines use woven labels for hem tags and leather patches for beanies to add retail-ready branding.

- Schools & Sports: From chenille letters for varsity jackets to mascot patches for little league uniforms, we support school spirit with durable products that last effectively for years.

Part 5: Creating Your Design

You don't need to be a professional graphic designer to order custom patches.

- Send Us Your Ideas: Upload your logo, a sketch, or just a description. Our team of professional digitizers will convert your artwork into a "stitch file" or mold proof.

- Digital Proofing: We send you a digital mockup showing exactly how the patch will look, including thread colors and dimensions. You can request unlimited revisions until it's perfect.

- Production & Shipping: Once approved, we begin production. Our efficient process ensures industry-leading turnaround times, and we offer rush options for tight deadlines.

Frequently Asked Questions (FAQ)

Q: What is the difference between embroidered and woven patches? A: Embroidered patches have a thicker texture with thread stitched onto a backing. Woven patches are flatter with thread woven together, allowing for finer detail and smaller text.

Q: Can you make patches with Velcro backing? A: Yes, we offer both hook-side only (to attach to existing tactical gear) or both hook-and-loop sides (so you can sew the loop side onto any garment).

Q: What is the minimum order quantity? A: We pride ourselves on flexibility. While ordering in bulk significantly lowers the price per patch, we can accommodate smaller orders. Please check our specific product pages for current minimums (usually as low as 10 or 50 pieces depending on the material).

Q: How durable are Iron-On patches? A: When applied correctly to cotton or polyester, our industrial-strength iron-on backing can withstand 20–30 wash cycles. For permanent attachment on workwear that is washed daily, we recommend sewing the patch down.

Q: Can I put a patch on a hat? A: Absolutely. Hats are one of the most popular uses for patches. We recommend leather or embroidered patches for caps. If you are applying it yourself, ensure you use a "cap heat press" to curve with the hat, or simply sew it on for the best fit.

Q: Do you offer metallic threads? A: Yes, we offer metallic gold and silver threads to give your design a premium shine. These are popular for military rank insignia and awards.

Q: What file format should I upload? A: We accept almost any file format, including JPG, PNG, PDF, and AI. High-resolution vectors (AI or PDF) are preferred for the clearest results, but our designers can work with whatever you have.

Q: How long does it take to get my patches? A: Standard turnaround time is typically 10–14 days after proof approval. PVC and Chenille may take slightly longer due to the mold and setup processes.

Ready to start? Browse our gallery below to see examples of Chenille, PVC, and Embroidered works we’ve created for satisfied customers. Select your style, upload your art, and let 24HourWristbands.com bring your custom patch design to life.